Experience. Quality. Precision.

That’s the Distron way.

Your One-Stop-Shop

For All Your EMS Needs

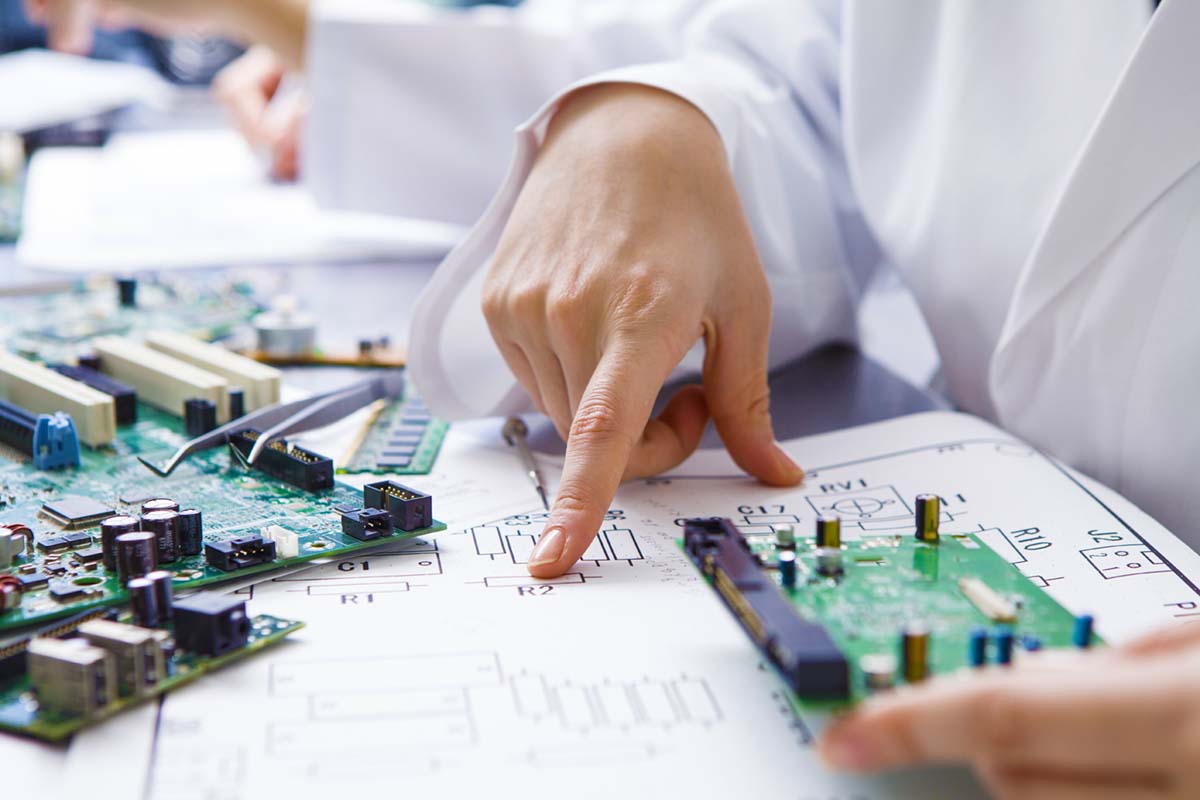

From prototyping to production, we take care of the entire process, combining efficiency, knowledge, and Tier 1 equipment and capabilities with the response, service-oriented focus of a smaller manufacturing company.

Electronic Contract Manufacturing Services

Prototyping

Through our New Product Introduction (NPI) services, Distron offers rapid proto-typing of printed circuit assembles to help meet the timely need of our customers requirements.

Inspection and Testing

Distron will assist with the design and application of product-specific test solutions. No matter your inspection needs, Distron has you covered.

Printed Circuit Board Assembly

When it comes to circuit board assembly, Distron achieves easy configuration adjustments, rapid setup, and pinpoint accuracy. From SMT to through hole, we can accommodate almost any process.

Product Warehousing & Fulfillment

Storage and delivery are hugely important factors in any electronic assembly services relationship. Distron combines decades of experience with longstanding relationships to meet your warehousing, fulfillment, and warranty needs.

Box Build Assembly / System Integration

Even the most complex electromechanical assemblies can be delivered through Distron’s technology, our decades of experience, and our team of trained operators. We manufacture to the IPC workmanship and ISO9001 quality standards in our 50,000 square foot facility.

Supply Chain Solutions

Distron knows the market, can predict where the market is headed, and will keep you ahead of any potential hiccups. We will work with you to tailor a supply chain solution that suits your needs.

Case Studies

Distron Corp has partnered with clients in many different industries and in many different disciplines. The one thing they had in common was their need for experience, quality, and precision.